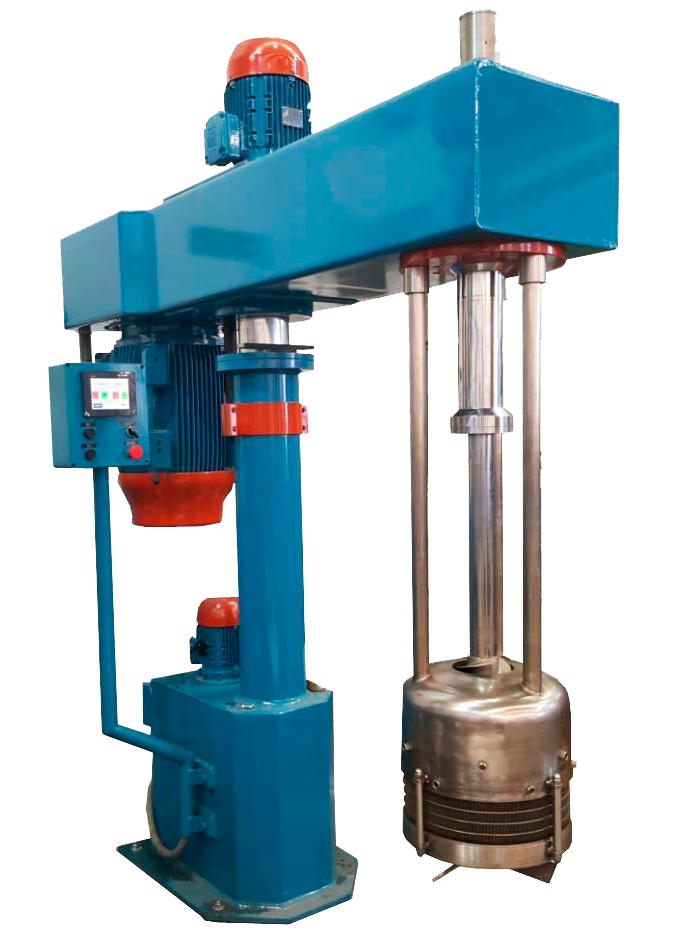

Disperser and basket mill with a capacity of 1 to 5 liters

This integrated equipment has all the components to perform a laboratory-scale batch test.

The equipment has a head that combines at one end a disperser with a 75mm disc to pre-spread the product to be ground, and at the other end a basket mill with all the features of our plant mills. In this way, dispersions and grindings can be carried out on a pilot scale with the same equipment. The lifting system of the head is electric, with reducer motor system.

The portable container is made of abrasion resistant stainless steel and has a volcable cooling jacket with a capacity of up to 5 liters.

All the components of the equipment are controlled by a PLC with touch screen with the adjustment variables of the head in use, either the disperser or the mill.

Dispersing head:

Asynchronous motor of 3 HP

75 mm. dispersing disc made of abrasion resistant stainless steel

Speed control by frequency inverter

Grinding head:

80 mm. diameter basket with slot from 0.25 to 0.5 mm

3 HP asynchronous grinding motor

Bolt system

80 mm diameter agitation impeller with interchangeable agitation propeller

Asynchronous agitation motor of 0.5 HP

Thermocouple temperature control

Control system:

Electronic individual speed motor control of disperser, basket and stirring

PLC with 5'' touch screen

Lifting system operated by contactors

Manufactured in IP55 Protection Efficiency Std. or High Efficiency explosive proof